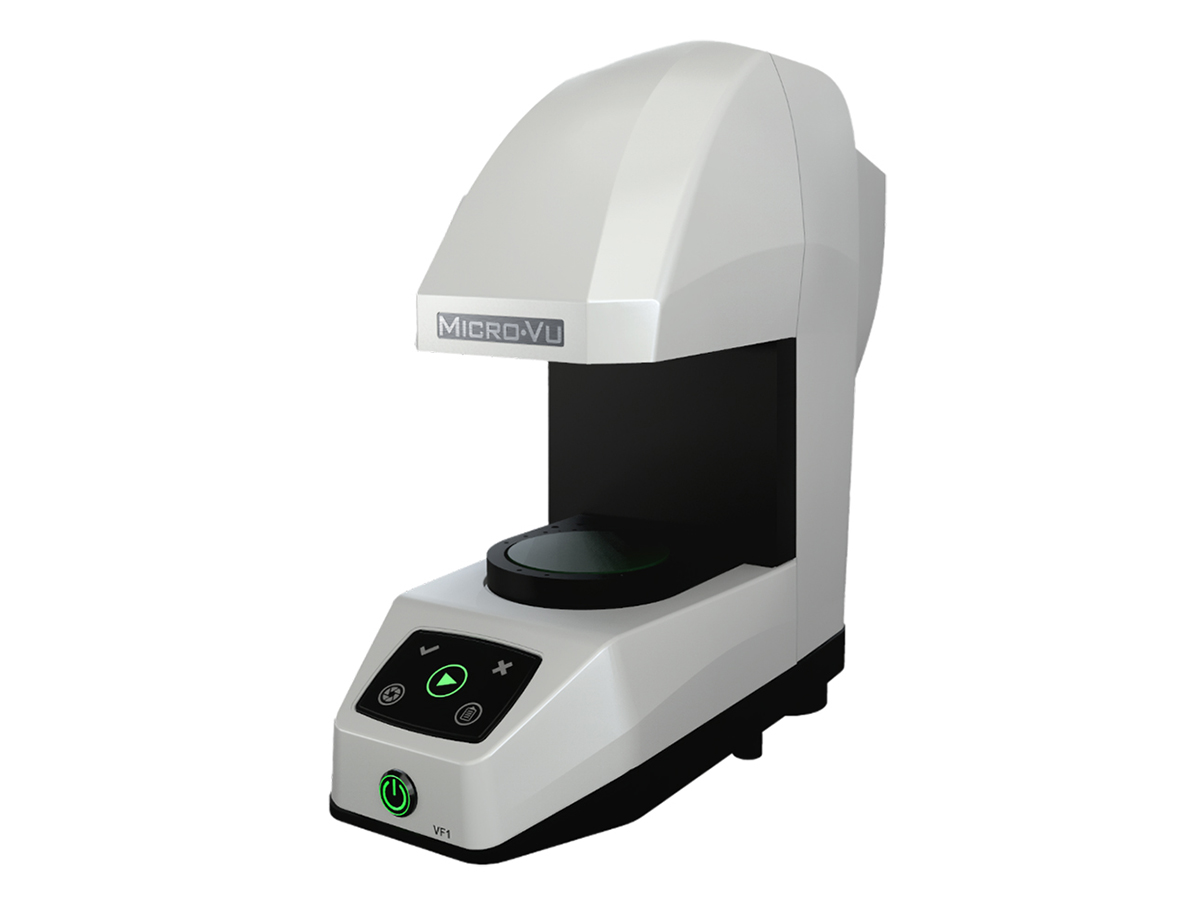

Field of View 3D Measuring Machine VF1

Ask for a priceSpecification

- XY Measuring Range: 69.3 × 49.6 mm — provides a wide field of view for part inspection.

- Measurement Depth Range (Z): 30 mm — large depth of focus suitable for varied part thicknesses.

- Accuracy at Calibration Plane: ≈ 5.0 µm — high-precision measurement at the focal plane.

- Accuracy Within ±10 mm of Calibration Plane: (5.9 + L/60) µm — consistent accuracy over depth.

- Machine Dimensions: 187 mm (W) × 394 mm (D) × 464 mm (H) — compact, desktop-friendly footprint.

- Machine Weight: Approximately 20 kg — lightweight design for easy placement and use.

- Single Snapshot Measurement: Captures and measures an entire part in one image.

- High-Resolution Camera: Delivers sharp images with defined edges and smooth gradients for precise feature detection.

- Scratch-Resistant Stage Glass: Durable work surface that resists wear and is easy to maintain.

- Automatic Part Identification: Detects part orientation automatically, reducing fixturing requirements.

Description

Field of View 3D Measuring Machine VF1 – is a compact, high-precision desktop measurement system designed for rapid and reliable dimensional inspection of parts without the need for manual focus adjustments. With its optimized imaging and lighting system, the VF1 delivers fast, repeatable measurement results in a space-efficient footprint — ideal for quality control in manufacturing and inspection labs.

Equipped with an intuitive touch panel interface, operators can automatically search for measurement programs, execute inspections, and view results with minimal setup time. The VF1 includes the latest InSpec Metrology Software, leveraging advanced edge detection algorithms to deliver sub-pixel accuracy and excellent repeatability.

The system’s compact profile light design ensures optimal illumination for precise feature detection and measurement.

Key Features

- Single Snapshot Measurement — Capture and measure the entire part in a single image for streamlined inspections.

- Large Measurement Range — Wide field of view minimizes measurement error and eliminates the need for focus adjustments.

- High-Resolution Imaging — Produces sharp, high-contrast images for superior feature detection and measurement accuracy.

- Compact Profile Light Design — Ensures consistent illumination for accurate edge detection across varied surface profiles.

- Automatic Part Identification — Detects part orientation automatically, reducing fixturing requirements.

- Scratch-Resistant Stage Glass — Durable stage surface for long-term use and easy maintenance.

- Integrated Software Control — InSpec Metrology Software manages imaging, lighting, and measurement operations for reliable results.

Technical Specifications

Measuring Capacity & Accuracy:

- XY Measuring Range: 69.3 × 49.6 mm

- Accuracy at Calibration Plane: ≈5.0 µm

- Within ±10 mm of Calibration Plane: (5.9 + L/60) µm

- Measurement Depth Range: 30 mm

Machine Dimensions & Weight:

- Size (W × D × H): 187 × 394 × 464 mm

- Weight: ≈20 kg

Software:

Includes InSpec Metrology Software for measurement automation, reporting, CAD import, and advanced feature evaluation.

Applications

The Micro-Vu VF1 is ideal for precision measurement and inspection in industries such as:

- Aerospace components

- Automotive parts

- Medical devices

- Packaging and plastics

- Precision engineering

Why Choose the VF1?

With its compact footprint, simple operation, and high-precision imaging system, the VF1 offers manufacturers a reliable solution for repeatable, efficient measurements. The integrated software suite enhances productivity by automating measurement sequences and reporting, making the VF1 a versatile tool for quality control and metrology environments.