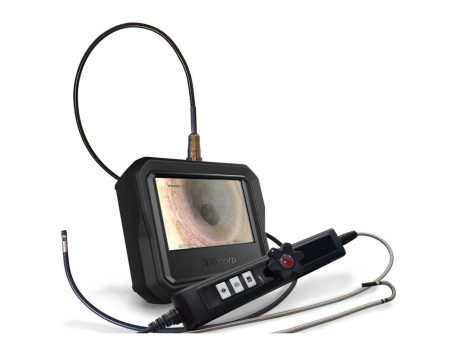

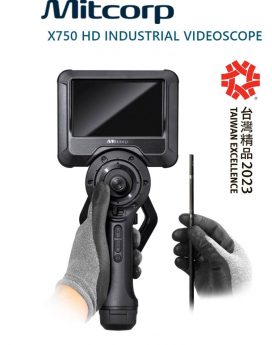

Industrial Videoscope, Mitcorp X600

Ask for a price

Ask for a price

Industrial Videoscope, Mitcorp X600

Specification

- High-Definition Imaging: Captures sharp and detailed photos and videos with Full HD resolution (1920×1080) for precise visual inspection.

- 5″ Touchscreen Display: Large 5 inch TFT LCD touchscreen with bright visibility and intuitive operation.

- Image & Video Storage: Supports micro SD card storage up to 64 GB for saving images and recordings.

- Rechargeable Li-Battery Power: Powered by a rechargeable lithium-ion battery for reliable portable use.

- Durable Construction: IP54-rated housing protects the videoscope from dust and splashes during industrial use.

- Drop Resistance: Withstands 1 m drop tests, enhancing durability in rugged inspection environments.

- Probe Compatibility: Works with interchangeable probes such as 3.9 mm 2-way/4-way articulated and 4.9 mm dual-camera probes.

- Probe Liquid Resistance: Compatible probes are IP67 certified, resistant to engine oil, transmission fluid, brake fluid, gasoline and water.

- Field of View & Depth of Field: Typical 90° field of view with 10 mm – 100 mm depth of field for effective inspection range.

- Data Connectivity: USB-C connection allows data transfer and charging, and may offer micro HDMI output for external displays.

Description

Industrial Videoscope, Mitcorp X600 – is a high-definition visual inspection instrument designed for professionals who require precise, reliable, and detailed remote visual inspections in industrial environments. With its bright touchscreen display, full HD imaging capabilities, rugged construction, and versatile probe compatibility, the X600 is ideal for inspecting engines, gears, welds, pipes, and other hard-to-access areas across automotive, manufacturing, aerospace, and maintenance applications.

Key Features

- Full HD Imaging: Delivers sharp, clear and bright high-resolution photos and videos (1920×1080) for accurate defect detection and visual analysis.

- 5″ TFT Touchscreen Display: Intuitive touchscreen with excellent brightness and visibility for real-time observation and review.

- Modular & Versatile Probe Compatibility: Works with a range of interchangeable probes (e.g., 3.9 mm articulation, 4.9 mm dual-camera) to suit specific inspection needs.

- IP54 Rated Housing: Rugged and reliable console with IP54 protection against dust and splashes, suitable for industrial environments.

- Drop Resistant: Designed to withstand drops from up to 1 m, enhancing durability for field use.

- Real-time Diagnostics & Data Sharing: Enables live inspection feedback, image capture, and USB-C data transfer and charging.

- Flexible Probe Options: Compatible with IP67 certified probes resistant to oils, fuels, and brake fluids — ideal for automotive and machinery inspection.

- USB-C Connectivity: Supports fast data transfer, real-time viewing on external devices, and efficient charging.

- Extended Storage Support: Allows micro SD storage (up to 64 GB) for saving high-resolution images and video files.

- Wide Operating Temperature: Reliable performance in diverse conditions (approx. -10 °C to 60 °C) for versatile field use.

Applications

The Mitcorp X600 is ideal for a wide range of professional and industrial visual inspection tasks, including:

- Engine and gearbox inspection

- Weld and structure integrity checks

- Pipe, duct, and tube inspection

- Manufacturing and assembly line verification

- Aerospace and mechanical component evaluation

- Maintenance and quality control in hard-to-reach areas