AeroCheck3

Ask for a priceSpecification

- Inspection Method: Portable eddy current (ET) flaw detector designed for aerospace and general industrial NDT applications.

- Frequency Range: Wide operating frequency range suitable for surface and near-surface defect detection using absolute, differential, and reflection probes.

- Display: High-resolution colour LCD display providing clear impedance plane and time-based signal visualization.

- Probe Compatibility: Supports industry-standard LEMO connectors, compatible with pencil probes, surface probes, bolt-hole probes, and rotary scanners.

- Rotary Scanner Support : Built-in rotary inspection capability, allowing direct connection and control of rotary drives for fastener hole inspection.

- Signal Processing: Advanced digital signal processing with adjustable gain, phase rotation, filtering, and mixing for optimized flaw detection.

- User Interface: Intuitive menu-driven interface with soft keys and programmable settings, enabling fast setup and repeatable inspections.

- Data Storage: Internal memory for saving inspection setups and test results, supporting trace comparison and reporting.

- Power Supply: Rechargeable internal lithium-ion battery, providing several hours of continuous field operation; unit can be used while charging.

- Construction & Portability: Lightweight, rugged housing designed for field and hangar environments, optimized for single-hand operation.

Downloads

Description

AeroCheck3 – Advanced Portable Eddy Current Flaw Detector

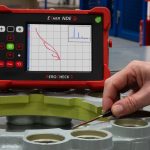

EtherNDE AeroCheck 3 is a high-performance, portable eddy current (ET) flaw detector engineered for demanding aerospace, MRO, and industrial non-destructive testing applications. Designed and manufactured by ETher NDE, a global leader in eddy current inspection solutions, AeroCheck 3 delivers precise, repeatable, and reliable detection of surface and near-surface defects in conductive materials.

Combining advanced digital signal processing with a compact and ergonomic design, AeroCheck 3 offers exceptional inspection performance while remaining easy to use, making it suitable for both experienced NDT inspectors and technicians in training.

Advanced Eddy Current Inspection Performance

AeroCheck 3 provides excellent sensitivity for detecting cracks, corrosion, and material discontinuities in aluminum, titanium, and other conductive alloys. The instrument supports a wide range of inspection techniques, including surface inspection, bolt-hole inspection, and component evaluation in both manufacturing and in-service environments.

Its powerful signal processing capabilities allow precise adjustment of gain, phase rotation, filtering, and mixing, enabling inspectors to clearly separate defect signals from material noise and lift-off effects. This ensures high detection reliability and confidence during critical inspections.

High-Visibility Display and Intuitive User Interface

The instrument is equipped with a high-quality colour LCD display that provides clear impedance plane and signal presentations. The display is optimized for use in various lighting conditions, from workshops to hangars and outdoor field inspections.

AeroCheck 3 features an intuitive, menu-driven user interface with soft keys and programmable inspection setups. This allows quick configuration changes, fast recall of saved inspection parameters, and consistent inspection procedures across multiple operators and shifts.

Rotary and Probe Compatibility

AeroCheck 3 includes built-in rotary inspection capability, allowing direct connection of rotary scanners for fast and efficient bolt-hole inspections without the need for external controllers. This significantly improves inspection speed and reduces equipment complexity.

The device is compatible with industry-standard eddy current probes, including absolute, differential, reflection, pencil, surface, and bolt-hole probes. Standard LEMO connectors ensure seamless integration with existing probe inventories and accessories.

Data Management and Traceability

To support quality assurance and repeatability, AeroCheck 3 allows the storage of inspection setups and reference traces directly in the instrument. Inspectors can compare live signals against stored references, improving defect recognition and ensuring consistent inspection results over time.

This functionality is particularly valuable in aerospace maintenance and regulated industries where traceability, repeatability, and documented inspection procedures are essential.

Portable, Rugged, and Field-Ready Design

Designed for daily professional use, AeroCheck 3 features a lightweight yet rugged housing that withstands the demands of industrial and aerospace environments. Its compact form factor enables comfortable single-hand operation and easy transport between inspection locations.

The internal rechargeable battery provides extended operating time, supporting full work shifts without frequent recharging. The unit can also be operated while charging, ensuring uninterrupted inspections during long or critical tasks.

Typical Applications

- Aircraft skin and structural inspections

- Fastener hole and bolt-hole crack detection

- Surface crack inspection in aluminum alloys

- Aerospace manufacturing quality control

- Maintenance, Repair & Overhaul (MRO) operations

- General industrial eddy current inspections

Key Advantages

- High-performance eddy current flaw detection in a portable format

- Excellent sensitivity for surface and near-surface defects

- Built-in rotary inspection capability

- Compatible with a wide range of industry-standard probes

- Intuitive operation with programmable inspection setups

- Reliable data storage and trace comparison

- Rugged, lightweight design for field and workshop use

EtherNDE AeroCheck 3 is the ideal solution for NDT professionals who require precision, reliability, and ease of use in a compact eddy current inspection system, making it a trusted tool for critical inspections in aerospace and industrial environments.