PhaseCheck

Ask for a priceSpecification

- Inspection Method: Eddy Current Testing (ET) using phase-plane analysis for surface and near-surface defect detection.

- Frequency Range: Wide eddy current frequency range suitable for general industrial, aerospace, and laboratory applications.

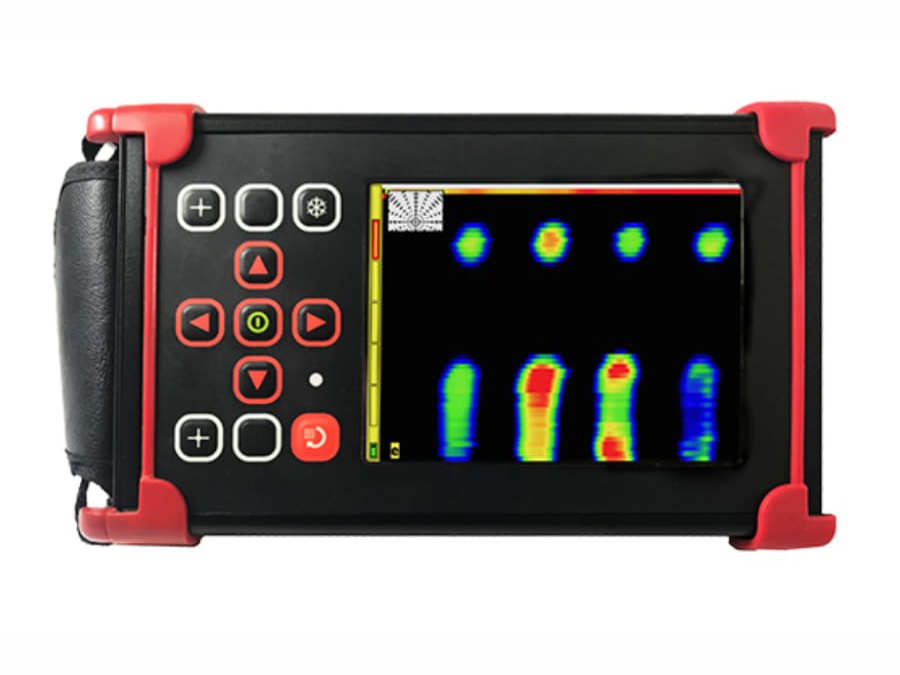

- Display: High-contrast colour LCD display for clear impedance plane signal visualization.

- Channels: Single-channel eddy current operation optimized for precise phase analysis.

- Probe Compatibility: Compatible with industry-standard eddy current probes, including absolute, differential, and reflection probes via standard LEMO connectors.

- Signal Processing: Digital signal processing with adjustable gain, phase rotation, filtering, and mixing for optimized defect detection.

- Data Storage: Internal memory for saving inspection setups and reference signals to ensure repeatability.

- Power Supply: Internal rechargeable battery providing several hours of continuous operation; device can be used while charging.

- Construction: Compact and rugged industrial housing designed for laboratory, workshop, and field use.

- Applications: Suitable for surface crack detection, material evaluation, conductivity-related inspections, and general eddy current testing.

Downloads

Description

PhaseCheck – Portable Eddy Current Flaw Detector for General ET Applications

EtherNDE PhaseCheck is a compact and versatile eddy current (ET) flaw detector, designed for a wide range of general industrial and aerospace NDT applications. Developed by ETher NDE, a globally respected manufacturer specializing in eddy current technology, PhaseCheck delivers reliable defect detection combined with simple operation and excellent value.

PhaseCheck is an ideal solution for inspectors who require a robust, easy-to-use eddy current instrument for routine inspections, training purposes, and standard ET applications where accuracy and repeatability are essential.

Reliable Eddy Current Inspection Performance

PhaseCheck provides dependable detection of surface and near-surface defects such as cracks, corrosion, and material discontinuities in conductive materials. It is suitable for inspection of aluminum, steel, stainless steel, and other non-ferrous and ferrous alloys.

The instrument offers precise control of essential eddy current parameters, including gain and phase rotation, allowing operators to clearly distinguish defect signals from lift-off and material variations. This makes PhaseCheck well suited for both inspection and educational environments.

Clear Display and Simple User Interface

Equipped with a clear, high-contrast display, PhaseCheck presents eddy current signals in an easy-to-interpret impedance plane format. The user interface is intentionally straightforward, enabling fast setup and minimal training requirements.

Logical menu navigation and clearly labeled controls help operators quickly adjust inspection settings and maintain consistent inspection procedures.

Probe Compatibility and Practical Flexibility

EtherNDE PhaseCheck is compatible with a wide range of industry-standard eddy current probes, including absolute, differential, and reflection probes. Standard probe connectors ensure easy integration with existing probe inventories and accessories.

This flexibility allows PhaseCheck to be used across multiple inspection tasks without the need for specialized or proprietary probes.

Portable, Rugged, and Field-Ready Design

Designed for daily industrial use, PhaseCheck features a compact, lightweight, and rugged housing suitable for workshop, site, and field inspections. Its ergonomic design supports comfortable handheld operation and easy transport between inspection locations.

The internal rechargeable battery provides several hours of continuous operation, supporting full inspection shifts. The instrument can also be operated while charging, ensuring uninterrupted availability during extended inspections.

Data Storage and Inspection Consistency

PhaseCheck allows storage of inspection setups and reference signals, enabling consistent inspection practices across multiple components and operators. This supports quality control requirements and improves inspection repeatability.

Typical Applications

- General surface crack detection

- Inspection of conductive components and assemblies

- Aerospace and industrial maintenance inspections

- Manufacturing quality control

- Training and educational use in eddy current testing

- General-purpose eddy current examinations

Key Advantages

- Reliable eddy current flaw detection in a compact format

- Simple, intuitive operation with fast setup

- Clear impedance plane signal visualization

- Compatible with a wide range of standard ET probes

- Lightweight and rugged design for industrial use

- Cost-effective solution for routine ET inspections

EtherNDE PhaseCheck is the ideal choice for NDT professionals and training centers seeking a dependable, user-friendly, and versatile eddy current flaw detector for everyday inspection tasks.