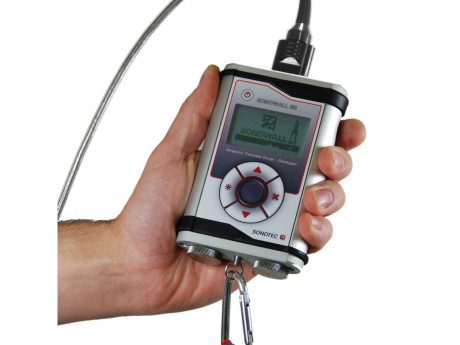

Ultrasonic Thickness Gauge US SONOWALL 70

Ask for a priceSpecification

- Measuring range: Up to 10000 mm

- Measuring method: Single-Echo, Echo-Echo

- Resolution: Up to 0.001

- Display: 5" TFT

- Dimensions: 195 mm x 115 mm x 40 mm

- Weight: 990 gr

Description

Ultrasonic Thickness Gauge US SONOWALL 70 – is perfectly suited for various ultrasonic testing applications such as non-destructive corrosion testing. The robust aluminium casing with IP67, a light weight of only 990g and high resolution anti-glare 5 ” graphic display make the SONOWALL 70 the ideal thickness gauge in harsh test environments.

SONOWALL 70 is the first thickness gauge in the market with intelligent probe identification. The extended probe management allows probe-specific information such as DAC-curves, delay lines, and serial numbers to be saved directly in the ultrasonic probe. In addition to various thickness applications, the device can be upgraded to a full-function flaw detector.

Corrosion and erosion defects are among the most common safety risks and reasons for production break downs in industrial environments such as refineries, pipeline networks, chemical plants, offshore platforms, storage tanks, etc. In order to maintain assets and to avoid hazards, ultrasonic thickness measurements are typically recorded frequently at pre-defined points creating a virtual grid on the surface of the test object. To help, collect, organize and report readings efficiently, the SONOWALL 70 ultrasonic thickness gauge can be equipped with the SONOGRID Corrosion Management Software.

Advantages at Glance

- Efficient and reliable Matrix Data Collection

- Visualization of test path through 3D Grid Creation

- Live Comparison Function and Corrosion Rate Estimation

- Easy Attachment of A-/B-scans and unlimited Text Comments

- Reproducibility through Grid Copy Function and Device Setup List

- Direct Data Export to MS-Excel and custom Report Generation

- Certified according to EN or ASTM standard

- SONO-ID for wireless probe recognition

- SONOGRID corrosion management software

- High temperature kit for corrosion testing up to 550°C

- IP67, aluminum housing