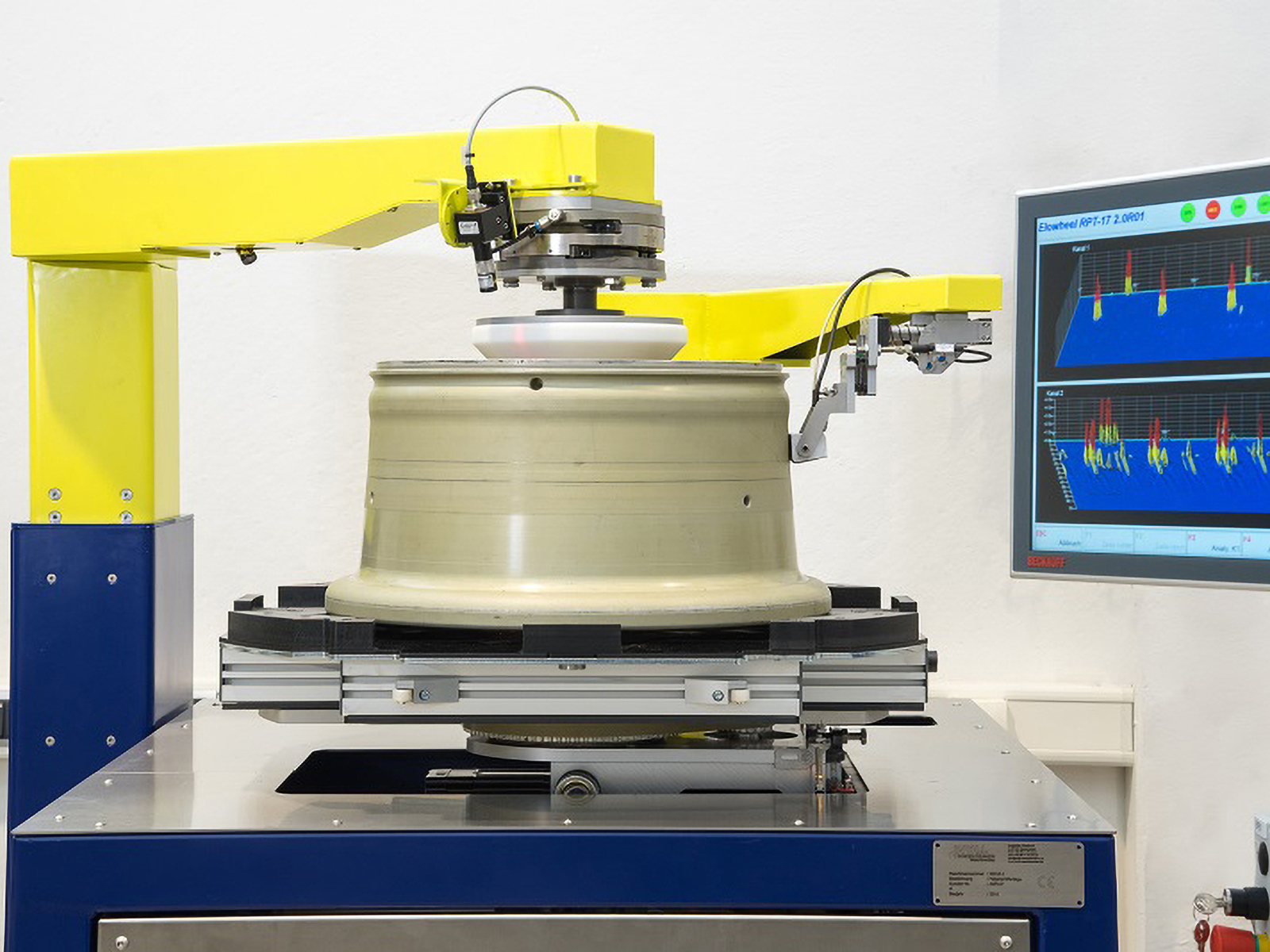

Eddy-Current Wheel Rim Inspection System ELOWHEEL

Ask for a priceSpecification

-

Components:

Testing stand

Rotating table

Pneumatic rim centering system - Max. rim diameter: 1000 mm

- Max. rim weight: 250 kg

- Dimensions: 1400 x 2300 x 2500 mm

- Power supply: 230 V / 2 kVA, 110 V / 2 KVA

- Compressed air supply: min. 6 bar, 1/4”

Description

Eddy-Current Wheel Rim Inspection System ELOWHEEL

Our new RPT17 Aircraft Wheel Inspection System is developed and manufactured in Germany. The system is the successor of the RPT16 – which is fabricated in the US and still placed on the market – and provides numerous innovations. Aircraft rims are are exposed to high mechanical loads, especially during take-off and landing. Additionally enormous thermal stresses occur while applying the brakes after touching down. Thus rims of both, civil aircrafts as well as military aircrafts, have to be inspected for any damages according to the regular maintenance intervals. Regions of maximum stresses, e.g. the bead seat radius and the bore holes, are of special interest. Using a modern eddy current testing instrument, the surface as well as the volume of the wheel rims is inspected by both, a high frequency and a low frequency probe simultaneously.