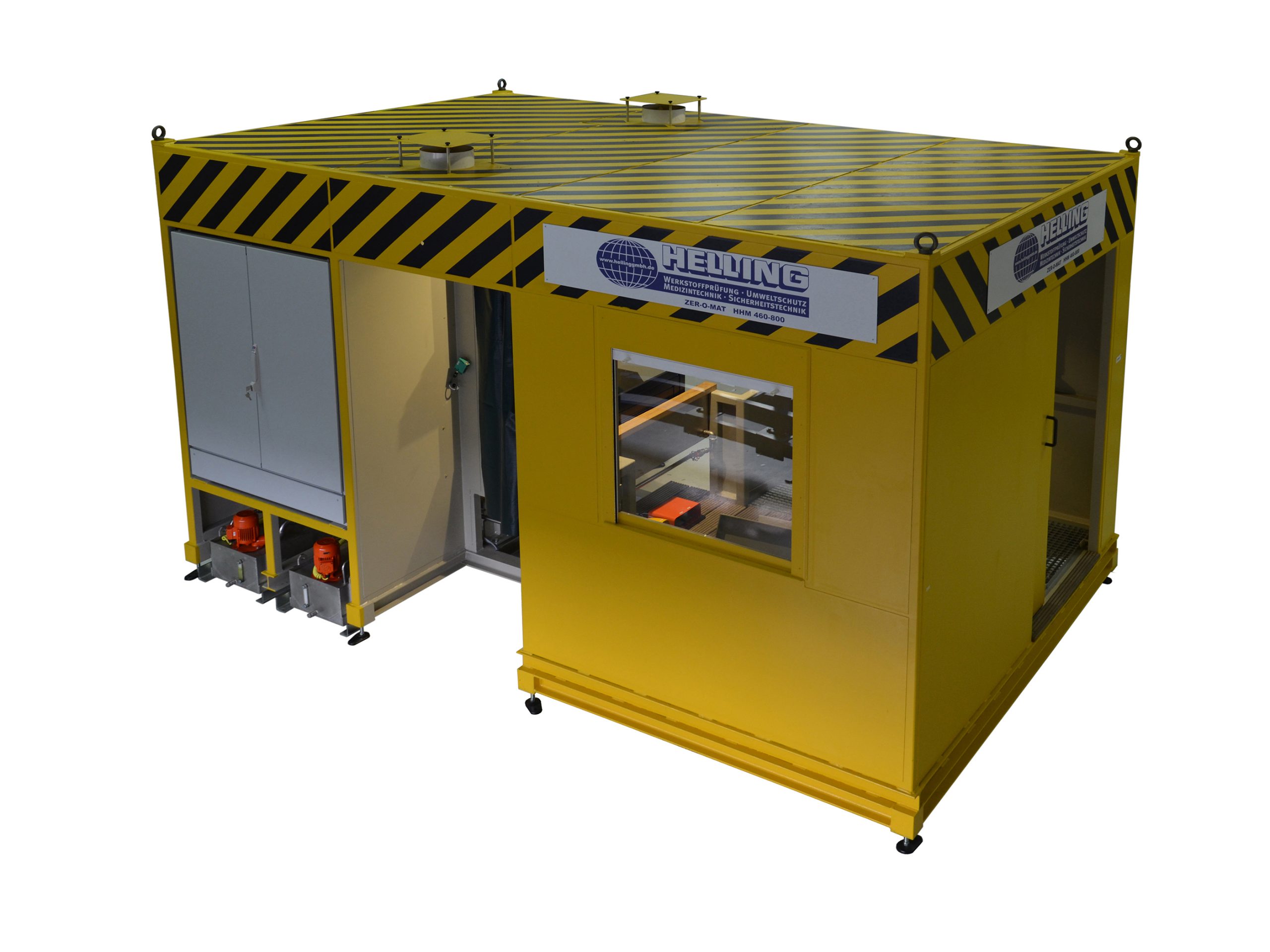

Magnetizing and Repair Station, ZER-O-MAT

Ask for a priceSpecification

- Supply voltage: 400 V / 50 Hz

- Control voltage: 230 V / 50 Hz

- Power: Max. 90 kVA

- Tangential field strength: > 24 A/cm2

- Part diameters: Ø 20 mm - 660 mm

Description

Magnetizing and Repair Station

ZER-O-MAT® devices are magnetizing and inspection stations designed for magnetic particle testing of pipes, rods, bars and other tubular parts with diameters from 20 up to 660 mm. The devices enable the user to find surface flaws of multidirectional orientation in one operation within short time. The use of these devices is not limited to round shaped products. They can be also applied for inspection of stocks and bars with square, rectangular or irregular shape. Furthermore, the ZER-O-MAT® stations are appropriate particularly for pipe-end testing.

Besides applicable for local inspection at repair stations, the devices can also be used for full length testing of tubular products, and an immediate repair, viz. directly after the (re-)inspection, is possible in both cases. An essential part of the device is the ZER O-MAT® solenoid coil, developed and patented by Helling GmbH. This coil has a characteristic U-shape, so that items to be inspected can be ”dipped” into the coil from above. The non-contact magnetization with the coil prevents burns at the tube surface and enables detection of surface flaws of multidirectional orientation within short time. The tangential field strength is min. 24 A/cm. ZER-O-MAT®- coils are operated with AC-current. Therefore, only the surface layer of the material is magnetized due to the skin effect. Thus, no demagnetization is necessary after inspection. The tube is turned during magnetization and inspection. The showering with a magnetic particle suspension starts at the coil bottom (04.00 – 08.00 h-position). The indications can be observed and evaluated in the turning-position above the coil (10.00 – 12.00 h-position). If the complete surface of the tube has to be tested, the tube must be moved helically through the coil. In this case the magnetizing system is designed for 100% make-time. The ZER-O-MAT® is equipped with an up-to-date, high power Slim-Line UV LED lamp. The lamp is vibration resistant and not affected by electromagnetic fields. Having no warm-up time the lamp is ready for operation immediately.

Specifications:

Power Supply: 400 V/50 Hz

Control Voltage: 230 V/50 Hz

Power Consumption: max.90 kVА

Current: min.250 A

Tangential Field Strength: ≥ 24 A/cm

Test piesce diameter: 20 – 660 mm