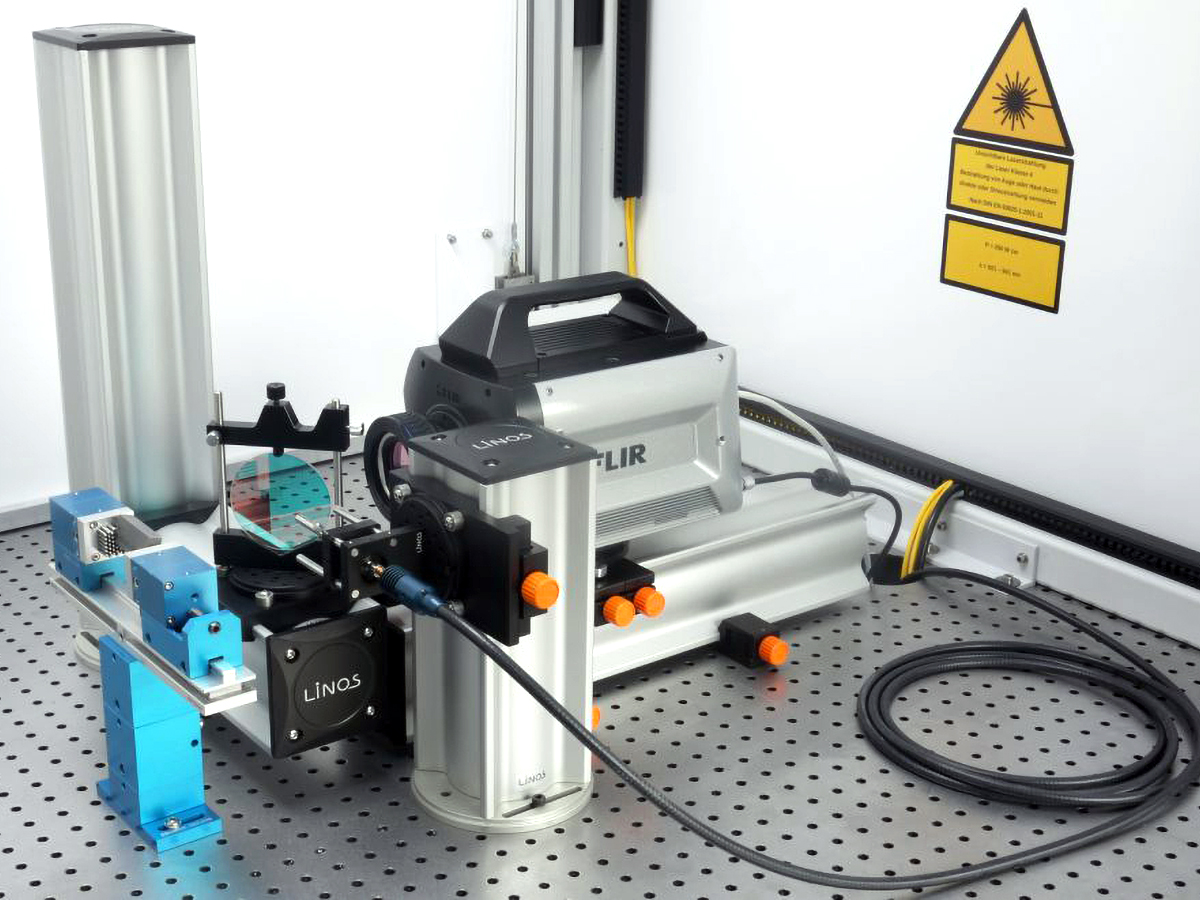

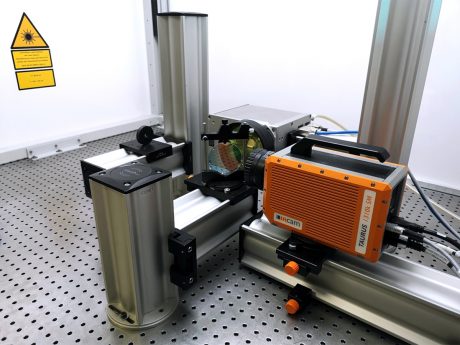

Automated Laser Excited Thermography LTvis ML

Ask for a priceSpecification

- Working principle: Laser Excited Thermography

- Applications: Non-destructive testing of laser welds

Description

Automated Laser Excited Thermography LTvis ML

The non-destructive testing of laser welds is carried out without contact using laser-excited thermography.

In the process, so-called ‘false friends’ can be unerringly identified among the weld seams, as the heat introduced by the laser with pinpoint accuracy cannot flow off or can only do so incompletely. The position of the weld seam can be automatically detected by imaging analysis with a high-resolution infrared camera, and the seam quality can be automatically evaluated with machine learning algorithms.

The inspection takes place in the production cycle and lasts only a few 100 milliseconds per inspected weld seam.

Ideally, the test takes place stationary (i.e. with the test objects at rest), but can also be carried out in continuous motion if necessary.

This NDT method is also available as a laboratory system.