Laser Scanning Thermography LTscan

Ask for a priceSpecification

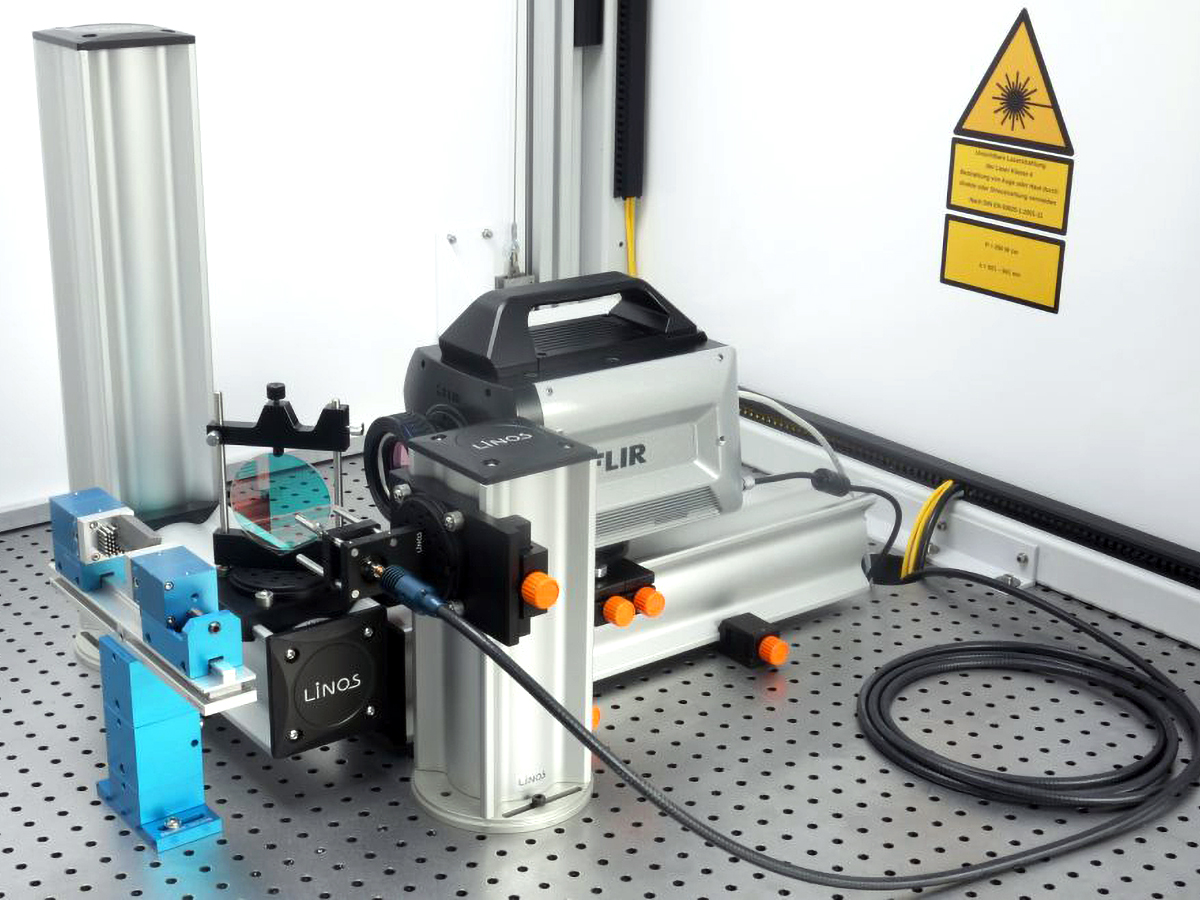

- Software: enables the controlling of Edevis lasers and a galvo scanner.

-

Applications:

Detection of cracks, adhesion issues or pores in potting compound

Detection of contamination on electrodes

Crack detection in green bodies and sintered parts

Description

Laser Scanning Thermography LTscan – non-contact crack detection, without any chemicals.

Laser scanning thermography is a non-contact, non-destructive testing method that is very well suited for crack detection in various materials, especially plastics and ceramics. The method is image-based and works well even under difficult environmental conditions. LTscan is expandable with all other Edevis excitation sources and software modules.

Principle of laser scanning thermography

Laser scanning thermography – also called flying spot thermography – is based on the relative motion between the excitation laser and the component.

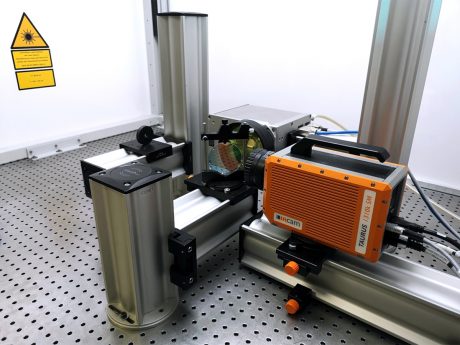

A laser point heats surface of the examined object. The lateral heat flow emanating from this point is stopped by thermal interfaces such as cracks. Due to the accumulating heat, the cracks can be detected by an infrared camera without contact. To inspect the entire component surface, the dot is moved across the surface by a galvo scanner. For large-area inspection, a laser line can be generated by fast periodic scanning in one direction, which is slowly moved over the component in the orthogonal direction. Depending on the component geometry, either individual points or contours can be scanned.

As an alternative to the galvo scanner, the line can also be generated via an optical element and the relative motion can be generated by means of rotation or translation axes. Combinations of galvo scanner and axes have also already been implemented industrially.