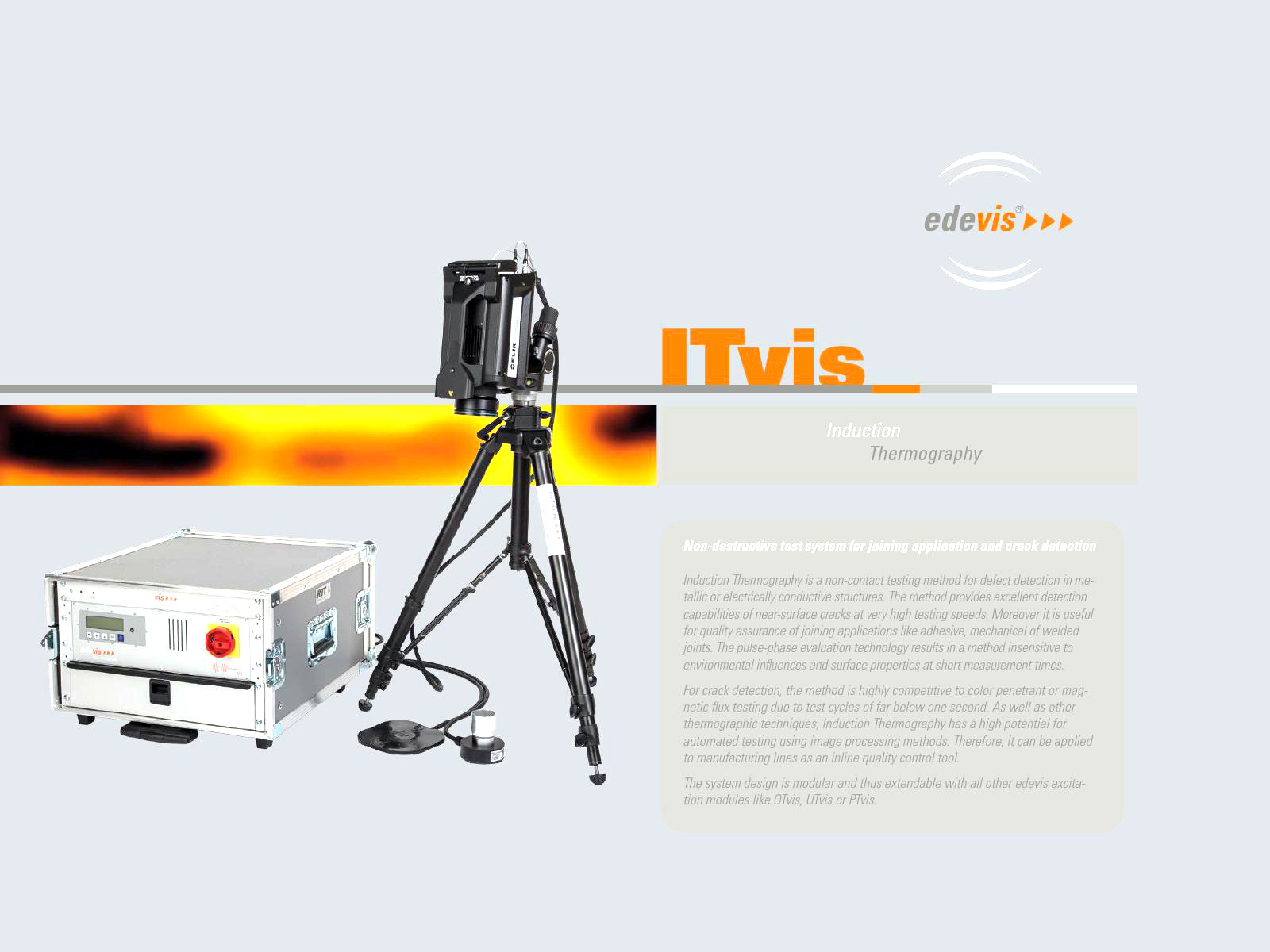

Induction Thermography ITvis

Ask for a priceSpecification

- Software: allows induction pulse and lock-in measurements

-

Applications:

Surface defects

Crack detection

Detection of overrolling

Joint connections

Weld seam inspection

Braze seam inspection

Adhesive joint inspection

Description

Induction Thermography ITvis

Induction thermography is a non-contact, non-destructive testing method that is very well suited for the non-contact and imaging characterisation of metal structures as well as metal-polymer composite materials. The method is particularly used when a non-contact measurement technique with short measurement times is required, e.g. for crack detection. Induction thermography is very robust and also works under difficult environmental conditions. The method is used in production as well as in maintenance. In contrast to dye penetrant testing or magnetic particle testing, the test specimens are tested completely without contact and without the use of chemical additives.

Principle

The surface of the examined object is heated by means of induction. The resulting current density distribution in the material is damaged by cracks or other irregularities such as overrolling. Heat backpressure causes “hot spots” to form on the surface, which are detected with an infrared camera. The sensitivity of the method can be significantly increased with the phase technique. Here, the intensity curve of the surface temperature is spectrally analysed by means of the Fourier transformation and broken down into a phase and amplitude image. In the phase image, interfering effects resulting from different emission coefficients or inhomogeneous excitation are significantly reduced.