Laser Excited Thermography LTvis

Ask for a priceSpecification

- Software: allows the complete control and activation of edevis lasers

-

Applications:

Testing of weld seams, brazed seams

Layer analysis (impurities, inclusions,…)

Layer thickness measurements

Testing of bonded joints

Description

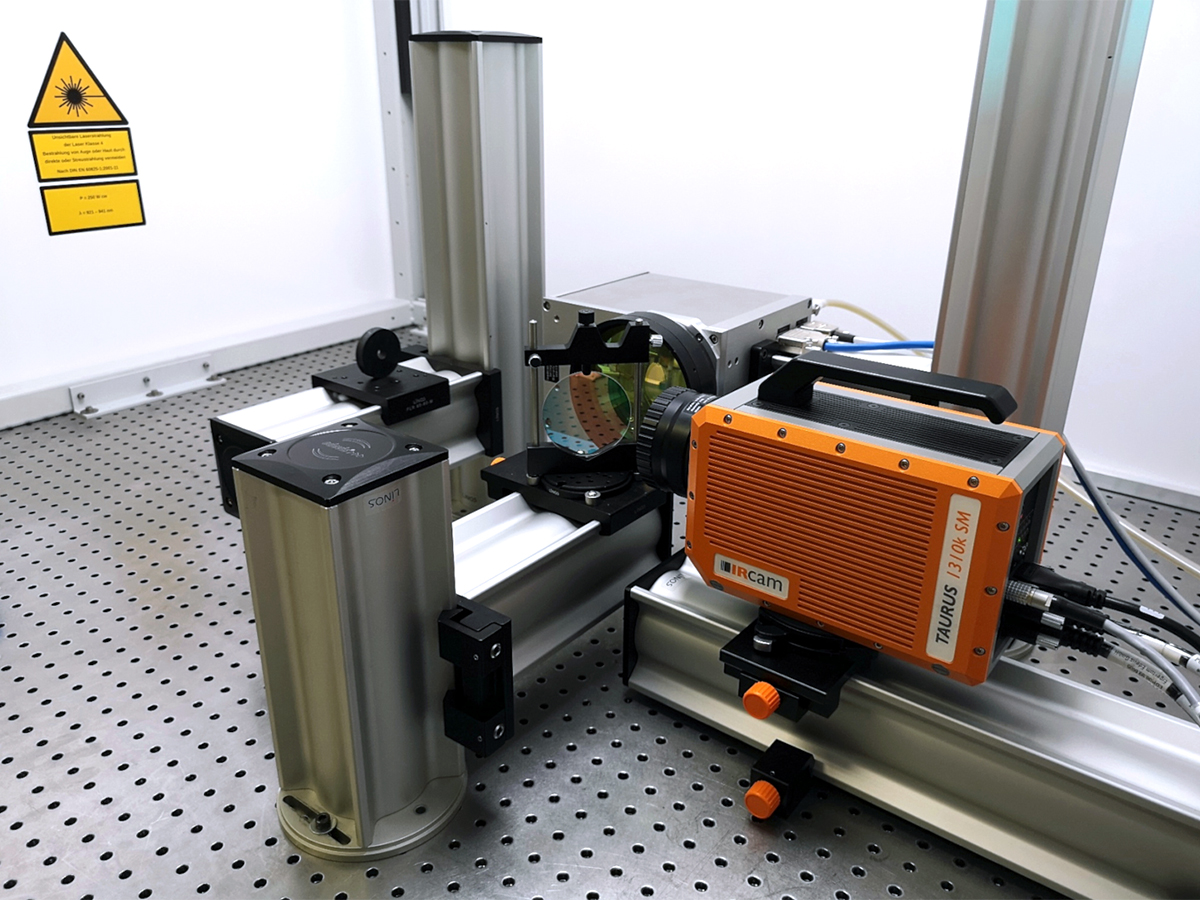

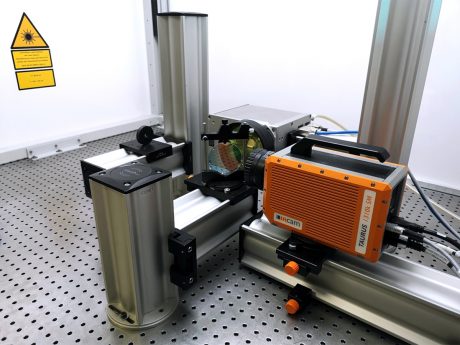

Laser Excited Thermography LTvis

Laser-excited thermography is a non-contact, non-destructive testing method that is very well suited for the characterisation of weld seams, thin layers and material joints. The method is particularly used when heating must take place very precisely in time and space and without contact. The energy can be applied in pulses or periodically. Due to the Fourier analysis, the technique is very robust and also works under difficult environmental conditions. LTvis is expandable with all other Edevis excitation sources and software modules.

Principle of Laser-excited Thermography

Laser thermography can be used both as pulse-phase thermography and as lockin thermography. The optical lockin thermography (LIT) method is based on heat flow analysis. It is often referred to as heat flow thermography. The surface of the examined object is heated with laser light. The resulting heat flow into the material is altered by thermal obstacles such as pores, detachments or material thickness variations of the object. Heat accumulation causes “hot spots” to form on the surface, which are detected by imaging with an infrared camera. The sensitivity of the method is very high due to the use of Fourier analysis. The evaluation is not only carried out on one image, but on a whole sequence of images. From this, a phase and amplitude image is calculated by means of a Fourier transformation. In the phase image, interfering effects resulting from different emission coefficients or inhomogeneous excitation are significantly reduced. The statement about the interface state and/or the material thickness or the coating thickness is now possible.